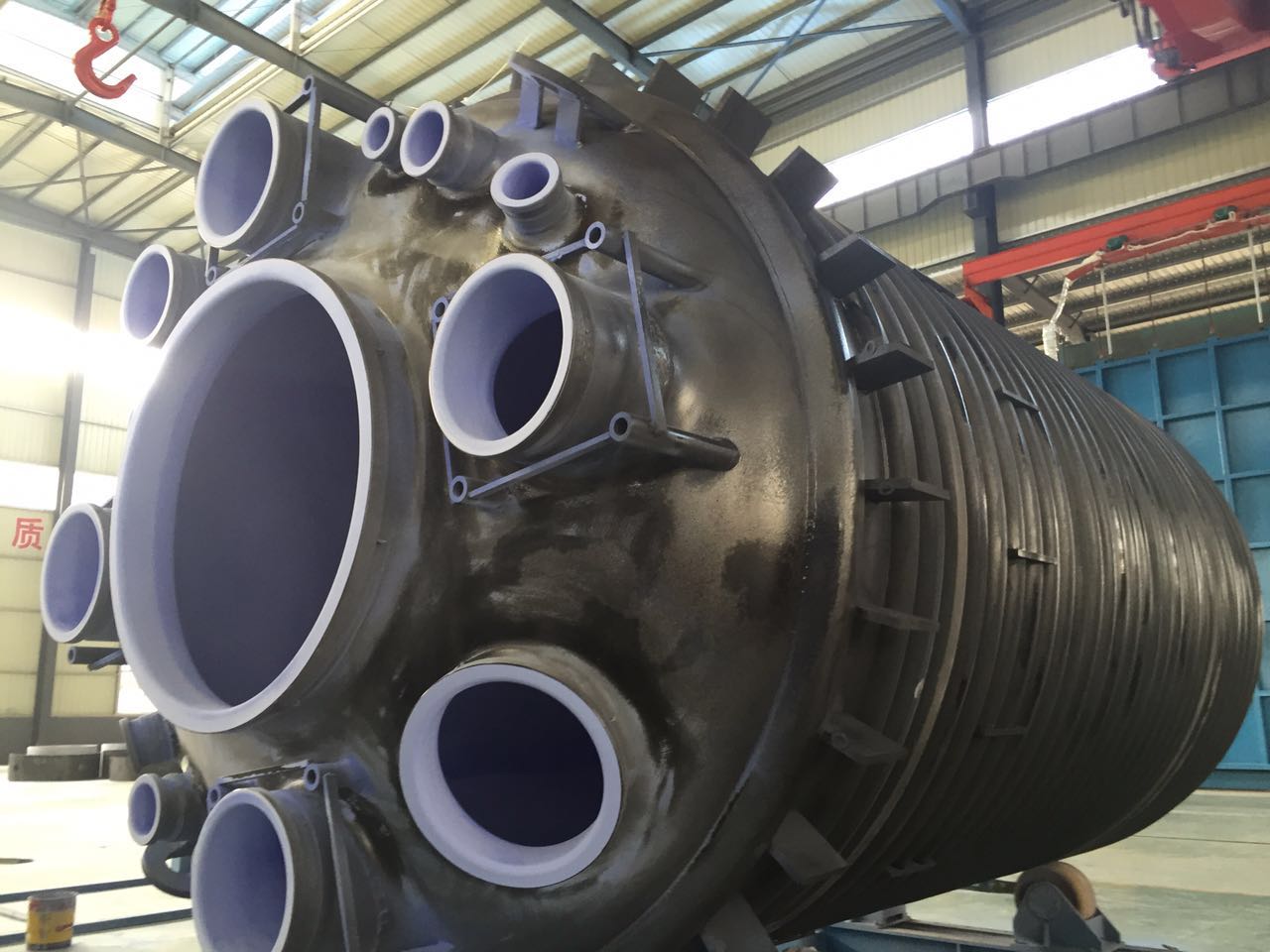

Performance comparison advantages and disadvantages of Glass lining Reaction kettle Semi-coil with the outer jacket:

1, the container type and safety: the way outside the jacket is a fixed heating or cooling with pressure operation, Semi-coil way is a liquid flow heating or cooling mode of operation. In terms of safety, Semi-coil method is more secure (not a solid gauge pressure vessel category).

2, the heat transfer effect: Semi-coil mode of heat transfer area, although smaller than the outer jacket of about 1/3, but the flow rate can be increased to 2 to 3 times the external jacket, the actual increase in heat transfer efficiency, Heat transfer medium is easy to form spoiler, short circuit, heat transfer is not uniform, Semi-coil way does not exist this defect. So the liquid heating medium, cooling medium Semi-coil way effect is significant. For the steam heating mode, taking into account Semi-coil way tube resistance, the outer jacket is better than the way the outer half tube.

3, stiffness: Semi-coil enhanced the reaction kettle stiffness, Semi-coil are open-type high-speed flow heat transfer method, reducing the inner sleeve of the external pressure, actually enhanced Reaction kettle stiffness.

4, corrosion resistance comparison: in the use of cooling brine cooling is easy to form on the metal H +, CL-ion corrosion, the outer jacket is easy to form a solution deposition corrosion; Semi-coil way using the top-down out of high-speed flow is not easy to form deposition , Not easy to cause corrosion on the wall.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

L8FR804(2).png)

.jpg)

.jpg)

|